Riso ComColor 7010R

Test Mode. 2. Numbering System

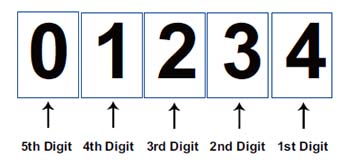

Meaning of the Numbers for Each Test Mode Digit

5th digit: 0 indicates test modes used by service technicians.

4th digit: Indicates the test mode category.

Note that there is some mixing of standard and optional components (such as for face up paper ejection). Numbers are defined in the following table.

3rd digit: Indicates the type of processing. Classified into sensor monitoring, drive checking, unit checking, initialization, data monitoring, and data editing. Numbers are defined in the following table.

2nd and 1st digit: Test mode detail number. No particular meaning in the numbering system itself.

| 4th digit | Category | Category Details |

|---|---|---|

| 0 | System | Controller PCB software, etc. |

| Image Adjustment | Items associated with image adjustment | |

| Test Printing | Execution of printing operations; settings that affect printing | |

| 1 | Engine | Paper supply and ejection, transfer, engine system, etc. |

| Image Adjustment | Items associated with image adjustment | |

| Test Printing | Execution of printing operations; settings that affect printing | |

| 2 | Print Heads | Ink path, ink heads, maintenance, etc. |

| 3 | OPTION Unit | Optional paper supply and ejection units |

| 4 | OPTION / Finisher | Finisher unit & IF unit for finisher |

| 5 | OPTION / Scanner | Items associated with the scanner |

| 6 | Engine and other | Paper Feed Settings and other |

| 7 | Engine and other | Paper Feed Settings and other |

| 8 | Other | Items associated with RFID tag control |

| 9 | Engine and other | Paper Feed Settings and other |

| 3rd digit | Processing Category | Test Mode Execution Details |

|---|---|---|

| 0-1 | Sensor Monitoring (S) | Checks the status of various sensors and switches. Status can be checked by letters or tones indicating the status. |

| 2-3 | Drive Checking (M) | Enables individual units such as motors to be activated or deactivated Actuators of clutches, fans, and other components can be driven for a specific period. |

| 4 | Unit Checking (U) | Enables execution of groups of components (in units) |

| 5 | Initialization (I) | Enables settings that were configured (in setting modes, for example) to be cleared or initialized |

| 6 | Data Monitoring (C) | Enables confirmation of numerical values managed as data in the system |

| 7-9 | Data Editing (D) | Enables system status or operation timing to be changed. However, be very careful when changing values because incorrect values may cause malfunction or other problems. |

Example Test Modes

01025

Sensor monitoring of the registration sensor (checks sensors for paper feeding and transfer system of the print engine system)

02305

Drive checking of ink cooling fans (confirms operation of actuators in the ink path of the print engine system)

03400

Unit checking of the auto-control stacking tray (AS) side paper guide (conducts coordinated operation of optional paper supply and ejection units)

04952

Stapler data editing (selection or adjustment of data when a stapler is installed in the finisher system)