Konica-Minolta bizhub C3350i

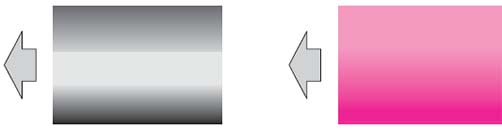

Troubleshooting. IQ. Uneven density 2

Initial troubleshooting procedure

| Step | Section | Check item | Result | Action |

|---|---|---|---|---|

| 1 | Paper Setting | The paper to be used for printing does not match the paper type and size of paper setting selected on the machine. | YES | Make the paper setting again on the machine. |

| 2 | IDC sensor | IDC sensor is dirty. | YES | Clean. |

| 3 | Service Mode -> Stabilizer | Select [Service Mode] -> [Imaging Process Adjustment] - > [Stabilizer] -> [Stabilization Only] and the image trouble is eliminated. |

NO | Go to the next step. |

| 4 | Service Mode -> Gradation Adjust | Select [Service Mode] -> [Imaging Process Adjustment] - > [Gradation Adjust] and the image trouble is eliminated. |

NO | Go to the next step. |

| 5 | Image check |

|

YES | Go to the 1-color troubleshooting procedure. |

| NO | Go to the 4-color troubleshooting procedure. |

1-color troubleshooting procedure

| Step | Section | Check item for the faulty color | Result | Action for the faulty color |

|---|---|---|---|---|

| 1 | Write section | Dirt or foreign matter on the dust-proof glass of the PH. | YES | Clean the PH window. |

| 2 | Charging section | Foreign matter on charging roller. | YES | Lightly wipe the surface clean of foreign matter using hydro-wipe (65AA-99##). Note: Do not apply a strong force to the surface of the charging roller, as doing so can damage the surface. |

| 3 | Photoconductor section | Dirt, scratches, or foreign matter on the photoconductor. | YES |

|

| 4 | Photoconductor section | Photoconductor drives faultily. | YES |

|

| 5 | 1st transfer section | Scratches or dirt on 1st transfer roller. | YES |

|

| 6 | Developing section | Toner bristles not even on the developing roller, resulting in a line or band. | YES | Replace the developing unit. |

| NO |

|

4-color troubleshooting procedure

| Step | Section | Check item | Result | Action |

|---|---|---|---|---|

| 1 | Paper path | There is dirty or foreign matter on paper path. | YES | Check and clean the paper path including the duplex section. |

| 2 | Transfer belt unit | Dirt, scratches, or foreign matter on the transfer belt. | YES |

|

| 3 | Transfer belt unit | There is a positive contact between the transfer belt application terminals and the high voltage unit connection terminals (Y: T1-4; M: T1-3; C: T1-2; K: T1-1). | NO | Clean or correct the terminal. |

| 4 | Transfer belt unit | Transfer belt rotates faultily. | YES |

|

| 5 | 2nd transfer section | Dirt or foreign matter on the 2nd transfer roller. | YES |

|

| 6 | 2nd transfer section | Faulty pressure/retraction operation of the 2nd transfer roller. | YES |

|

| 7 | 2nd transfer section | There is a positive contact between the application terminals of the 2nd transfer and the connection terminals (T2, E1) and ground terminal of the high voltage unit. | NO | Clean or correct the terminal. |

| 8 | Fusing unit | There is dirty or foreign matter on paper path of fusing unit. | YES | Clean. (Disassembling the fusing unit is prohibited.) |

| 9 | Service Mode -> Initialize + Image Stabilization |

Select [Service Mode] -> [Imaging Process Adjustment] - > [Stabilizer] -> [Initialize + Image Stabilization] and [Gradation Adjust], and the image trouble is eliminated. |

YES | Readjust. |

| NO |

|