| Step |

Section |

Check item for the faulty color |

Result |

Action for the faulty color |

| 1 |

Write section |

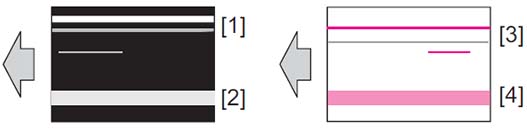

Sharp white line or colored line is blurry. |

YES |

Clean the PH window. |

| 2 |

Charging section |

Foreign matter on charging roller. |

YES |

Lightly wipe the surface clean of foreign matter using hydro-wipe (65AA-99##).

Note: Do not apply a strong force to the surface of the charging roller, as doing so can damage the surface. |

| 3 |

Photoconductor section |

There is a positive contact between the electrostatic charger application terminals and the high voltage unit connection terminals. |

NO |

Clean or correct the terminal. |

| 4 |

Developing section |

There is a positive contact between the developing bias application terminals and the high voltage unit connection terminals (Y: B4; M: B3; C: B2; K: B1). |

NO |

Clean or correct the terminal. |

| 5 |

Photoconductor section |

Scratches on photoconductor. |

YES |

- Clean.

- Replace the drum unit.

|

| 6 |

Photoconductor section |

Toner line or dirt on photoconductor. (improper cleaning) |

YES |

Replace the drum unit. |

| 7 |

Photoconductor section |

Faint lines evident on the entire surface as if the surface were brushed off. |

YES |

- Select [Service Mode] -> [Counter] -> [Life] and check the counter value of the Drum Unit.

- Replace the drum unit having the greatest counter value with a new one. (Not the drum unit of the color that has developed the lines, but the drum unit having the greatest counter value)

|

| 8 |

1st transfer section |

There is a positive contact between the transfer belt application terminals and the high voltage unit connection terminals (Y: T1-4; M: T1-3; C: T1-2; K: T1-1). |

NO |

Clean or correct the terminal. |

| 9 |

1st transfer section |

Scratches or dirt on 1st transfer roller. |

YES |

- Clean.

- Replace the transfer belt unit.

|

| 10 |

Developing section |

Toner bristles not even on the developing roller, resulting in a line or band. |

YES |

Replace the developing unit. |

| NO |

Replace the PH unit. |

| Step |

Section |

Check item |

Result |

Action |

| 1 |

Paper path |

There is dirty or foreign matter on paper path. |

YES |

Check or clean the paper path including the duplex section. |

| 2 |

Transfer belt unit |

Lines that can be removed by cleaning are evident on the transfer belt. (improper cleaning) |

YES |

- Check or clean the cleaning blade.

- Replace the transfer belt unit.

|

| 3 |

Transfer belt unit |

Dirt, scratches, or foreign matter on the transfer belt. |

YES |

- Clean.

- Replace the transfer belt unit.

|

| 4 |

Transfer belt unit |

There is a positive contact between the transfer belt application terminals and the high voltage unit connection terminals (Y: T1-4; M: T1-3; C: T1-2; K: T1-1). |

NO |

Clean or correct the terminal. |

| 5 |

2nd transfer section |

Dirt or foreign matter on the 2nd transfer roller. |

YES |

- Remove the foreign matter.

- Replace the transfer roller unit.

|

| 6 |

2nd transfer section |

There is a positive contact between the application terminals of the 2nd transfer and the connection terminals (T2, E1) and ground terminal of the high voltage unit. |

NO |

Clean or correct the terminal. |

| 7 |

Fusing unit |

There is dirty or foreign matter on paper path of fusing unit. |

YES |

Clean. (Disassembling the fusing unit is prohibited.) |

| 8 |

Fusing unit |

Scratches on belt or roller in fusing unit. |

YES |

Replace the fusing unit. |

| NO |

- Replace the high voltage unit.

- Replace the base board.

|

| Step |

Section |

Check item |

Result |

Action |

| 1 |

Original |

Original is damaged or dirty. |

YES |

Change the original. |

| 2 |

When original glass is being used |

A fault occurs in the image read through the original glass. |

YES |

Go to step 5. |

| 3 |

When DF is being used: 1st side |

A fault occurs in the image read from the 1st side while DF is being used. |

YES |

Go to step 11. |

| 4 |

When DF is being used: 2nd side |

A fault occurs in the image read from the 2nd side while DF is being used. |

YES |

Go to step 18. |

| Main body side_original glass |

| 5 |

DF side_ Original pad |

Original pad of DF is dirty. |

YES |

Clean. |

| 6 |

Original glass |

Original glass is dirty. |

YES |

Clean. |

| 7 |

Shading sheet |

Shading sheet is dirty. |

YES |

Clean. |

| 8 |

End face of original is reproduced as a line |

Select [Service Mode] -> [Machine] -> [Scan Area] -> [Scanner Image Side Edge] and make the necessary adjustment, and the image trouble is eliminated. |

NO |

Go to the next step. |

| 9 |

Line occurring due to faulty shading |

Select [Service Mode] -> [Machine] -> [Scan Area] -> [Image Position: Leading Edge] and make the necessary adjustment, and the image trouble is eliminated. |

NO |

Go to the next step. |

| 10 |

Parts along scanning path |

Mirror, lens, light guide or reflectors is dirty. |

YES |

Clean. |

| NO |

- Replace the LED exposure unit.

- Replace the CCD unit.

|

| Main body side_DF original reading section |

| 11 |

Main body side_reading section |

Document reading glass of main body is dirty. |

YES |

Clean. |

| 12 |

DF side_ document reading glass cleaning brush |

Document reading glass cleaning brush of DF is dirty. |

YES |

Clean. |

| 13 |

Main body side_shading sheet |

Shading sheet of main body is dirty. |

YES |

Clean. |

| 14 |

When DF is being used: 1st side: End face of original is reproduced as a line |

Select [Service Mode] -> [ADF] -> [Original Stop Position] -> [Sub Scanning Direction 1-Side] and make the necessary adjustment, and the image trouble is eliminated. |

NO |

Go to the next step. |

| 15 |

Service Mode -> Read Pos Adj |

Select [Service Mode] -> [ADF] -> [Read Pos Adj] -> [Auto Adjust] and the image trouble is eliminated. |

NO |

Go to the next step. |

| 16 |

Line occurring due to faulty shading |

Select [Service Mode] -> [Machine] -> [Scan Area] -> [Image Position: Leading Edge] and make the necessary adjustment, and the image trouble is eliminated. |

NO |

Go to the next step. |

| 17 |

Parts along scanning path |

Mirror, lens, light guide, or reflectors is dirty. |

YES |

Clean. |

| NO |

- Replace the LED exposure unit.

- Replace the CCD unit.

|

| DF side_original reading section |

| 18 |

CIS glass cleaning |

CIS glass is dirty. |

YES |

Clean. |

| 19 |

CIS reading section |

CIS reading section is dirty. |

YES |

Clean. |

| 20 |

CIS cleaning brush |

CIS cleaning brush is dirty. |

YES |

Clean. |

| 21 |

Shading sheet |

Shading sheet is dirty. |

YES |

Clean. |

| 22 |

When is DF being used: 2nd side: End face of original is reproduced as a line |

Select [Service Mode] -> [ADF] -> [Original Stop Position] -> [Sub Scanning Direction 2-Side] and make the necessary adjustment, and the image trouble is eliminated. |

NO |

Go to the next step. |

| 23 |

When DF is being used: 2nd side: Home Read Position |

Select [Service Mode] -> [ADF] -> [Home Read Position Adjust] and the image trouble is eliminated. |

NO |

Go to the next step. |

| 24 |

Scanning section |

CIS reading section is dirty. |

YES |

Clean. |

| NO |

Replace the CIS module. |